What is Kanban Development?

Kanban development is a popular Agile method with practices emphasizing project transparency and effective collaboration. It was first developed by Japanese engineer Taiichi Ohno in the 1940s and gained popularity when implemented as part of the world-famous Toyota Production System (TPS).

Since then, Kanban has infiltrated allied manufacturing industries and software development. It is a preferred project management technique for many teams worldwide and, together with Scrum, is adopted by 57% of organizations.

Compared to other Agile methods, Kanban is relatively simple to adopt, and teams who employ the framework can immediately see its benefits. Like other Agile methods, it is critical to understand Kanban’s principles and practices to unlock its full value.

This blog includes a detailed discussion of the meaning, history, principles, and key practices of Kanban development.

What is Kanban?

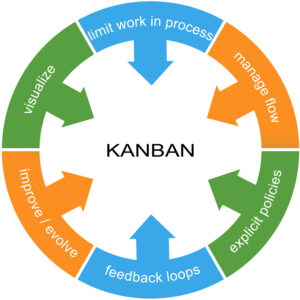

Kanban is a workflow management method for improving, defining, and managing services that deliver knowledge. It aims to help teams maximize efficiency, completely visualize workflows, and continuously improve their work.

Kanban is a Japanese word that means ‘visual board’ or ‘signboard.’ It stems from the Kanban method, first defined in 2007. At its core, Kanban is a just-in-time (JIT) production process designed to optimize the flow of components and raw resources used to create an end product.

Kanban development was derived from the Lean production system used at Toyota in the 20th century. In the late 1940s, Toyota implemented and began optimizing the just-in-time manufacturing approach to production based on the same model that supermarkets in Japan were using to stock their shelves.

Supermarkets only stock enough products to meet consumer demand; this practice optimizes the flow between the consumer and the supermarket because inventory levels match consumption patterns. This unique production system laid the foundation for a Lean production system used at Toyota, where production was based on consumer demand rather than the standard ‘push’ practice of producing goods and thrusting them into the market. Minimizing waste activities without sacrificing productivity became its core purpose, with the main goal of creating more value for customers without generating higher costs.

The principles and practices used by Toyota became known as the Toyota production system (TPS). Manufacturers around the world, and later software development experts, co-opted this system to improve sustainability and profitability and reduce waste.

One of the key pillars of Kanban development is that it is a ‘pull,’ not ‘push,’ system. Practically, this means that new work is pulled into the system once previously assigned work has been completed rather than new tasks being pushed into the workflow once created.

The inversion from ‘push’ to ‘pull’ is significant because development becomes a consequence of, and is related to, customer demand. The team only spends time on tasks that are valuable to the customer, thereby reducing the potential for waste (of time, resources, and money).

Kanban development shares several core concepts with TPS in keeping the development pipeline lean and free of clutter by:

- Enhancing task prioritization while leaving space for agility and adaptability

- Improving organization

- Increasing productivity by maintaining a consistent ‘flow’ of development tasks

- Fostering team collaboration

Kanban Boards

A Kanban board is used to visualize and optimize workflows among all Kanban teams. It can involve drawing a Kanban system on a whiteboard or even a wall section where it  serves as a focal point for daily meetings. Teams may also employ virtual Kanban boards for easier collaboration, traceability, and accessibility (such as with distributed teams).

serves as a focal point for daily meetings. Teams may also employ virtual Kanban boards for easier collaboration, traceability, and accessibility (such as with distributed teams).

A Kanban board’s function, whether digital or physical, is to ensure the team’s workflow is standardized, their work visualized, and all dependencies and blockers identified and resolved as soon as possible.

The board employs color-coded cards to represent individual tasks, each of which represents a part of the overall development project. Each of the cards are sorted into one of three categories: to-do, in progress, or done. The team only takes up and actively works on a limited number of tasks that best use its capacity.

Tasks are picked up by team members and moved through various stages of completion as they progress. Visualizing the workflow in this manner makes it rapidly clear whether bottlenecks inhibit the progress of tasks toward completion or other inefficiencies in the team’s workflow.

Team managers can map the workflow to meet the unique process of any team based on the team’s structure, objectives, and size.

Kanban Cards

Every work item for Kanban teams is represented as a separate card on the Kanban board. The main purpose behind representing work as cards on the Kanban board is to enable team members track their work progress through the visual workflow.

A Kanban card features vital information about a particular work item, giving the entire team full visibility into the task. Information on the card may include a brief description of the task, who is responsible for it, the estimated delivery timeline, and so on.

Kanban cards allow team members to see the state and associated details of every work item at any point in time, ensuring increased focus and immediate identification of dependencies and blockers.

Core principles of Kanban development

Like other Agile methods, Kanban is guided by specific principles and values that help teams improve their work and results. Some of the key values of Kanban, according to the Agile Alliance, include transparency, balanced viewpoints and capabilities, collaboration, flow, and customer focus.

In addition to its values, Kanban’s core principles are as follows:

Visualize the workflow

Kanban’s first principle pertains to the visualization of work items and projects. Unlike other business process approaches, Kanban does not prescribe a workflow. Rather, it requires all work items to be documented in an easily envisioned manner for all.

In Kanban, visualizing work implies a clear and high-level understanding of the process and each piece of work – as represented by a Kanban card – as it moves through the process. Enhancing visibility in your operations is vital to identifying areas that require improvement. Teams find that collaboration and communication instantly increase by visualizing work, and bottlenecks become apparent.

Visualizing the workflow across a team also helps establish transparency and accountability. This is invaluable, particularly for development teams that require coordinated efforts to work efficiently.

Limit Work in Progress (WIP)

Limiting WIP urges your team to finish outstanding tasks before taking up new work. Thus, work currently in progress must be finalized and marked done; this creates accommodation in the system so that the team can pull in new work.

The main concept in Kanban is to have each piece of work progress from one level to the next efficiently. Limiting WIP helps avoid the accumulation of work and bottlenecks. Tasks must be limited to what can be reasonably managed and performed at a given time.

This principle takes its cue from Little’s Law. According to Little’s Law, which is related to Queue Theory, the average number of items in a queue is equal to the average arrival rate and time spent. Therefore, assuming a stable system, fewer queue items will translate to lower time spent on queue and faster arrival rates.

In relation to Kanban, the Law holds that the items listed as WIP equate to the team’s total throughput and lead time. Throughput refers to the rate at which tasks exit the WIP stage, while lead time is the average time each task spends in the system. Thus, an optimal number of WIP items will typically enable faster task completion rates and times.

Of course, this law might operate differently given a larger pool of variables. But what Little’s Law teaches is that teams can work faster and more efficiently when they can find the sweet spot between too many WIP tasks and too few tasks. Further, by intentionally throttling the number of items on queue, the team can speed up the time and rate at which they complete their work.

That’s why limiting WIP is regarded as a core Kanban principle – it enables a predictable system that enjoys a smooth, well-managed flow. Additionally, setting limits helps teams identify top priority jobs that require completion first. You’ll be able to spot opportunities in the system where a slight increase or decrease in queued tasks can improve productivity. Likewise, it helps teams and individuals reduce errors, move faster, collaborate effectively, reduce the constant need to re-prioritize items, and avoid the problems caused by task switching.

Mange flow

Kanban’s third principle focuses on the flow and process of production. Just like managing the task queue is critical, flow optimization is also a critical element of fluent Kanban teams.

Flow describes how work moves through the Kanban system. Bad flow happens when work starts and stops abruptly, moves between different steps without any significant progress, or spends a lot of time in wait states. Good flow means that work moves from one step to another in a fairly linear path, with little to no delay in between.

As the first principle (visualization) shows, the Kanban board serves as a great tool for observing how work moves from one operational stage to the next. This grants managers a clear view of the team’s workflow and identifies potential bottlenecks or interruptions in the normal flow.

A great first step towards optimizing for flow is by using WIP limits. Limiting WIP eliminates excess active work, which is one of the primary obstacles to good flow. As a team, you must keep each piece of work moving forward efficiently.

- Some of the ways you can discuss methods to improve flow include asking questions like:

- How can we move existing cards off the board?

- Has any task been in the same position for more than a day? How do we get the work moving again?

- Is there any work that needs help finishing before pulling up the next?

Process policies can also consistently maintain good flow by making rules that cards, and every team member, must follow. These might include:

- How to effectively handle bottlenecks

- Conditions that must be fulfilled before team members can draw a new card into an active lane

- Rule regarding work sitting for longer than usual periods

By tracking the flow of work through a system, issues can be promptly identified and changes measured for effectiveness. Focusing on flow optimization can help development teams stay flexible, productive, and efficient on their path of ongoing improvement.

Make process policies explicit

As part of the visualization process, it is important to explicitly define and clarify the project’s policies, guidelines, or process rules. By drafting a definitive process guideline, you form a common basis for all participants to understand how any work gets done in the system.

The policies can be for each column, at the board level, or a swim lane level. These policies can be an entry-exit benchmark for each column or a checklist of steps for each work item type – basically, anything that helps team members effectively manage workflow on the board.

Explicit policy examples could include who pulls what, when tasks get pulled, the description of individual columns or lanes, or when a task is defined as completed. It is important that these policies are clearly defined and explained so the team can have open discussions about improvements.

Give Feedback and Improve

Lastly, continuous improvement through collaboration should be a guiding focus as your team moves tasks through the various Kanban stages.

Kanban development is an evolutionary, not revolutionary, process. It is not meant to force a complete change on your team. Rather, it helps you improve at a gradual pace and adopt small changes that your team can handle easily and which crucially encourage continuous improvement.

It’s great practice to start with design boards that accurately reflect your current process. You can carefully and thoughtfully practice continuous improvement from the design boards. Identify where feedback might merge with incoming iterations to foster an enduring process of meaningful changes that help your team effectively and efficiently improve performance.

This principle encourages the use of the scientific measurement and experimentation method to form a hypothesis, test it, and make changes that reflect test findings.

As you use your Kanban board, you’ll notice situations for practicing continuous improvement. Enforce these changes one at a time, and measure their impact so you can maximize your learning.

Benefits of Kanban for engineering teams

Kanban has several benefits that teams can start to see from week one. You’ll typically note that team members experience less overwhelm and enjoy more of the clarity and headspace that encourages quality work. Likewise, Kanban teams experience less stress and burnout due to the sustainable engineering practices and work pace that the framework encourages.

Teams adopting Kanban can also look forward to the following benefits:

- Prevent multitasking: While multitasking can be beneficial in high-pressure projects, it tends to prioritize task completion over quality. Instead, Kanban keeps teams focused on one task at a time, thereby enabling greater quality. Additionally, since WIP queues are set based on task priority, teams do the most important work first, thereby removing the need for destructive speed or multitasking.

- Optimize work pace: WIP limits in Kanban help teams keep an ideal work pace without exceeding optimal capacity. In Kanban boards, the WIP limit is the doorkeeper that ensures you only start as much work as you can finish in the iteration, preventing the accumulation of unfinished work that floods your processes.

- Increase efficiency: Introducing and experimenting with the WIP limit practice in your system is an indicator of constant improvement. Thereby, Kanban improves your throughput so you can continually meet and exceed customer expectations.

- Reveal bottlenecks: Kanban helps reveal process breakers and prevents team members from recurring context switching between tasks. WIP limits have a positive impact on improving your team’s efficiency and productivity.

Let i3solutions help improve your development workflow

Using the Kanban development method helps increase accountability, transparency and collaboration which maximizes time and improves efficiency. i3solutions has spent 25 years perfecting our development methodologies to deliver the highest possible business value to our customers. Whether you need guidance on your Kanban methodologies or are looking for a solution developed using Kanban, i3solutions has the knowledge and expertise you need.

Leave a Comment